| 404 |

|

DECEMBER 6TH, 1945 |

A Thrilling New Big-twin Rapide

Vincent-H.R.D. Design

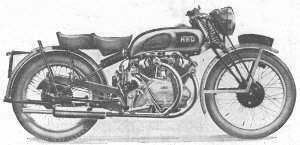

Vincent H.R.D.s are concentrating upon one model - the famous "Rapide." As a result of this policy and of their now magnificent production facilities, it is anticipated that the price of the 998 c.c. big-twin will show only a very small increase over the £145 of 1939, though in this country plus, of course, Purchase Tax. And this is in spite of the new and greatly improved specification. The whole conception is new, and the machine almost bristles with fresh features and "riders points."

In size and even in weight the 998 c.c. Vincent-H.R.D. "Rapide" is a 500! Great pains have been taken to ensure cleanliness in design and freedom from all oil leakage.

The aim in the new model is to provide a big-twin "thousand" which has outstanding speed and acceleration and first-class road manners coupled with the weight, the wheelbase and the ease of handling of a super five-hundred. It is when the eye roams from the combined engine and gearbox to the wheels that full realisation begins to dawn that here is a cobby, extraordinarily compact machine which in every direction, either than it's larger engine and its greater performance, is a five-hundred.

With the new design the wheelbase is 3in. shorter than on the old Rapide. It has been reduced to 56in. which is the same as on the old Vincent H.R.D. 500 c.c. T.T. machines. The weight has also been reduced. It is anticipated that this will be 400 to 405 lb. - again very much that of a five-hundred.

Engine Forms a "Tie"

As with every Vincent-H.R.D. that has been produced, there is pivot-action rear springing. The construction of the machine is, however, very different from the past. At first glance it may appear to be on standard lines. Then it is noticed that there is no front down tube - indeed there are remarkably few tubes. That robust, clean-looking engine-gear unit provides the link between the "backbone" of the machine, the top member, and the rear chainstays. With the so-called diamond frame the engine forms the tie between the front-down tube and the seat tube - does so automatically; in the new Rapide, by ingenious design, full use is made of the opportunity the 50-degree twin proffers. As with diamond-frame machines the crankcase forms a tie, but this is a wide, extremely rigid engine-cum-gear unit designed specially, while as for the link between the top frame member and the bottom half of the unit, this comprised not the widely set cylinder holding-down studs as such, but studs within these studs. In other words, there are tubular studs for cylinder and cylinder-head holding -down purposes and, running down the axis of these are solid studs, approximately 3/8in diameter, to carry the frame loads. Each of the two types of stud has its own thread in the crankcase, and the two are thus independent of each other.

Construction of the top member is unusual, and as

regards dimensions and strength, reminiscent of a lorry chassis. Running

backwards from the forged steering head lug, and riveted to it, is a six-pint

oil tank which is a deep "fl???" in construction. This is some 3 1/2 in.

wide and has a mean height of about 5in. Over this fits the 3 3/4

gallon stainless steel fuel tank, which narrows towards the rear for riding

comfort and is of semi-pistol grip type. The width at the riders

knees, incidentally, is approximately 11in. An interesting feature

is that there is an air space between the oil and fuel tanks amounting

to about 1 1/2 sq. in. on each side so that air can pass along the sides

of the former tank, which by its design has a very large surface area.

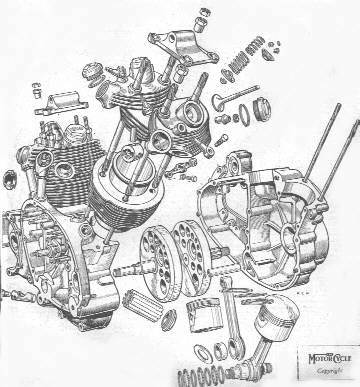

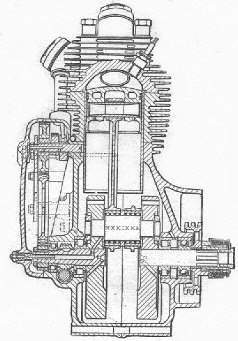

A special drawing revealing the detail construction of the new Rapide engine and the manner in which the parts go together. The ingenious valve gear is worthy of particularly close examination.

As in the past, enclosed coil springs link the area of the top member

with the seat stays. The pivoted chainstays follow standard Vincent-H.R.D.

but, as on the earlier layout, the Skefko taper-roller bearings are carried

in the chain-stay members. These bearings are of the same size and type

as those for the front and rear wheels. Friction dampers are incorporated

at the bottom of the rear of the special Feridax Dualseat, which has the

nose, rear and the front of the rear seat picked out in maroon to match

the panels on the stainless steel tank. It is a very special Dualseat

with the tyre inflator running lengthwise in it and completely hidden and

a tooltray under the front portion. This tray pulls out like a drawer

and has a felt inlay to provide a rattleproof housing for each of the tools.

The question of the toolkit is being investigated; it is hoped to be able

to accommodate in addition a repair outfit, spare plugs and replacement

lamp bulbs.

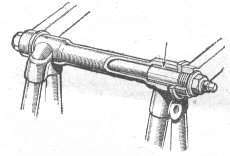

Oil-impregnated porous-bronze bushes and side-thrust washers are used in the new front forks.

The front forks are of link- or girder-type, but redesigned with the object of providing forks which will operate efficiently over thousands of miles without attention, even lubrication. They have Nitralloy spindles working in porous bronze, oil-impregnated bushes. Side-thrust washers at the top links are also of this oil-retaining bronze. An anti-rattle mounting in the form of a compressed rubber bushing is provided for the knob of the steering damper, which can therefore be left right "off" without any clatter occurring. Another improvement is a Bakelite knob for adjusting the friction dampers incorporated in the bottom links.

So much for the frame and front forks. The wheels are: Front, WM 1-20 rim fitted with a 300-20 ribbed tyre; rear, WM 3-19, with a 3.50-19 studded tyre. The aim has been to provide a front rim that is light for road-holding and a rear one which is sturdy and fully equal to high-speed sidecar work.

While the foregoing is the standard specification, there is room for 4.50-18 tyres both front and rear. Vincent H.R.D.s want to fit stainless steel rims, but the difficulties are to get them and at what is construed a reasonable price. The alternative is chromium-plated rims. A single security bolt is being fitted front and rear and the wheels are being balanced on racing-car lines - by bolts and lead washers.

Both wheels have their twin brakes - "Duo" brakes - one each side, and are of the Vincent-H.R.D. really quick to detach type, which does not involve the use of tools. The hubs are now aluminium die-castings. The brakes, incidentally, are 7in. in diameter, with 7/8in. wide linings. A feature of the rear wheel assembly is that the final driving chain, thanks to the tommy arrangement for the rear wheel spindle and hand-operated stainless-steel chain adjusters, which are of the self-locking "click" type, is also adjustable without the employment of tools.

The front forks are of link- or girder-type, but redesigned with the

object of providing forks which will operate efficiently over thousands

of miles without attention, even lubrication. They have Nitralloy spindles

working in porous bronze, oil-impregnated bushes. Side-thrust washers

at the top links are also of this oil-retaining bronze. An anti-rattle

mounting in the form of a compressed rubber bushing is provided for the

knob of the steering damper, which can therefore be left right "off" without

any clatter occurring. Another improvement is a Bakelite knob for adjusting

the friction dampers incorporated in the bottom links.

So much for the frame and front forks. The wheels

are: Front, WM 1-20 rim fitted with a 300-20 ribbed tyre; rear, WM 3-19,

with a 3.50-19 studded tyre. The aim has been to provide a front rim that

is light for road-holding and a rear one which is sturdy and fully equal

to high-speed sidecar work.

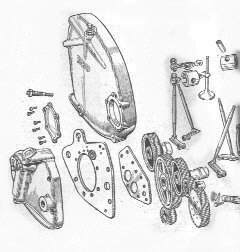

How the oil tank and the drop-forged steering head form the backbone of the machine

[oops*] using only one cylinder; a low-lift rear stand - approximately 2in lift, with the rear mudguard hinged just behind the lifting handle at tyre level; a very wide hinge is used to give the mudguard lateral rigidity. On the handlebars are three levers - clutch, front brake and exhaust-valves lifter - a built-in horn push that is an inch or more in diameter for ease of operation, and two twist grips. One of these last, of course, controls the throttles of the two carburettors; the other, which has a powerful click-over spring action, operates the dip-switch.

Considerable thought had been expended upon securing a riding position which is truly adjustable. The footrests are mounted on long hangers with taper fixings at the top and a series of holes near the bottom, which, the shank of the kick-starter pedal being inside the hanger and the exhaust system being of the low-level type, means that the footrests can be set in any position that might conceivably be desired. The footrest on the kick-starter side - the kick-starter can be fitted on either side - is provided with a folding pad and it is proposed to fit a simple automatic arrangement whereby on the kickstarter pedal being depressed the pad flies out of the way, to be pressed down again when the engine has started.

Both the brake pedal and the foot gear change pedal are carried on the forgings that form the footrest hangars, so the pedals remain in the same relative position to the footrests. If a rider wishes to adopt a racing position he can use the pillion footrests and reverse the gear and brake pedals on their mountings so that they face to the rear and are under his toes. The pillion footrests are on plates that extend rearwards from the engine-gear unit. Thus they are fully sprung: they are also fully adjustable since there are three holes available and, in addition, they can be swivelled. The kick-starter pedal, with its curved shank or arm, is unusual. It is designed to give first-class leverage, the start of the effective stroke being at approximately the 10 o'clock position and the end at roughly 8 o'clock. It is of the folding type, and it and the gear pedal will probably be of stainless steel.

An adjustable spring blade forms the tensioner for the triplex primary chain. Note the manner in which the 50-watt dynamo is driven.

Naturally the 998 c.c. engine - 84 x 90 mm. - is based on the highly successful Rapide of the past. It has only a moderate compression ratio (6.8 to 1), and is designed to provide high power with docility, long life and freedom from the need of frequent decarbonisation. The output, it is stated, is over 45 b.h.p. at 5,300 and the makers quote the speeds on petrol of 73 to 80 octane at 110 m.p.h. in top gear (3.6 to 1), 95 - 98 in third (4.3), 80 - 83 in second (5.6) and over 60 in bottom (9.6).

The engine is of the high-camshaft or "semi o.h.c." camshaft type with total enclosure of the valve gear. There are also twin camshafts, one for each cylinder, with a large idler pinion between the engine-shaft and camshaft pinions. An idler pinion is also employed to the (B.T.H. or Lucas) automatic advance-and-retard magneto: this incorporates a rotary release valve to release the crankcase pressure and ensure a clean engine. An aluminium outer steady plate is provided for the timing gear.

Rear Cylinder Offset

Both cylinders have their exhaust ports to the front, and the rear one is 1 1/4in. this permitting a direct air blast. The connecting rods are set side by side on a 1 9/16in. diameter crankpin and are each mounted on 135 3mm. diameter, 5mm. long uncaged rollers.

The mainshafts are 1in. in diameter, pressed into the flywheels and have on the driving side one large roller bearing and one large ball bearing, and on the other two roller bearings, one large and one small. The connecting rods are of nickel-chrome steel of about 65 tons/sq. in. Heat-treated R.R.53 B light alloy is used for the cylinder heads, which have shrunk-in valve seats, austenitic-iron inlets and aluminium-bronze exhausts. The finned cylinder jackets are also of light alloy - silicon alloy for low expansion. The cylinder liners, which have a lip at the top and are, therefore, definitely held apart from the shrunk fit, project into the crankcase for approximately half their lengths.

A works drawing showing the arrangement of the main and big-end bearings.

"Silichrome" inlet valves and austenitic-steel exhaust valves are employed. The ports of the latter are 1 7/16in. diameter, and of the former the diameter is 1 11/16in; the ports can be opened up very considerably if desired. Amal carburettors with vertical mixing chambers and 1 1/16in. bore are fitted.

Design of the valve gear, with it's total enclosure and not even a rocker shaft hole through which oil can seep, is highly ingenious. As usual in Vincent-H.R.D. engines, the valves have twin guides, but now, for reasons of neatness and because at the r.p.m. involved there is little, if anything, to lose, the springs are of the coil-type instead of hairpin. Tappet adjustment is effected by removing the large die-cast hexagonal caps. By undoing the tapped adjuster the rider can, if he desires, pull both the push-rod and the valve rocker out of the tappet-adjuster hole. Stainless steel push-rod tubes are fitted. Incidentally, the oil feed to the rockers is taken from the return form the oil pump - rotary-cum-reciprocating plunger type - to the oil tank, so that the oil is warm and flows readily. All oil is pumped straight through a felt filter of over 50 sq. in. total area mounted in a housing cast in the crankcase and removable for cleaning by undoing one cap on the near side; draining the oil tank beforehand is not required.

Pistons are "Specialloid," each with two 1/16in. wide pressure rings and an 1/8in. scraper. The dynamo is of 50-watt output with the voltage-control unit mounted alongside. Plug covers are being standardised.

Drive from the engine to the gear box is by a 3/8in. pitch triplex chain, which is provided with an adjustable spring-blade tensioner on the lower run. The gear box, which is lubricated separately from the engine, is a Vincent-H.R.D. product and of racing-type design, with alternate dogs cut back approximately 1/16in. for ease of engagement. It is of constant-mesh type with a positive foot change.

Other points are: A 6in. ground clearance, a saddle height of approximately 28 1/2in. with the rider seated, and a choice of 10 or 12 rear chain wheels, with 46 T. standard and others - the rear wheel will accept one each side and can be changed round in the fork ends - available as extras to all who want them. The clutch? A new clutch of self-energising type, a clutch that has the advantage of excellent heat-dissipation properties, has been designed.

Delivery of the Rapides should start about March, and may be earlier.

At the present time probably 20 per cent. of the parts for the first 300

Rapides are ready. In the case of some parts, where material is readily

available, sufficient for the first 500 have been made.

| 407 |

|

DECEMBER 6TH, 1945 |

* If someone can supply the missing text I'd be very thankful.

Site by ManxNorton.com